Weaving

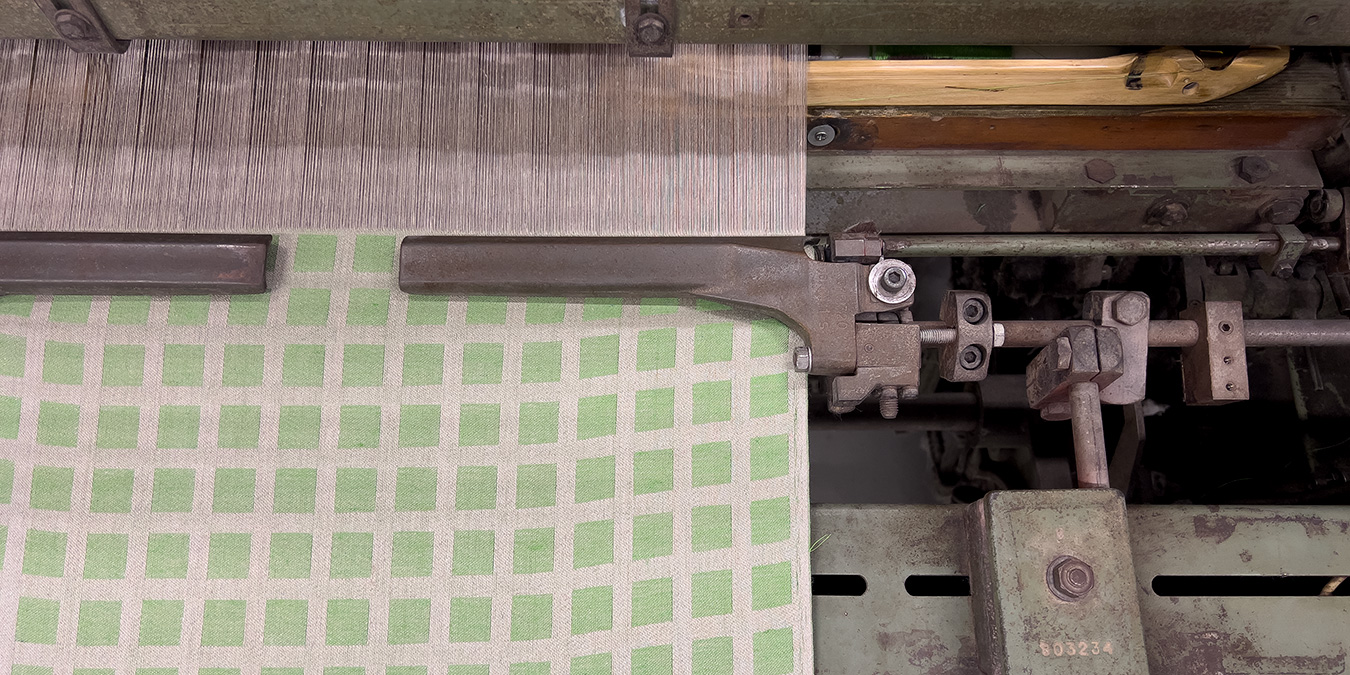

Once the warp and sleying are complete, we tie the warp onto the loom, and then it's time to begin weaving. We are one of the few weaving mills in the world specialized in weaving everything with 100% linen. Linen fabric is both durable and environmentally friendly, but linen is a natural fiber and a living material that makes weaving with 100% linen a delicate task requiring knowledge and precision from both weavers and machines. These factors lead most companies to incorporate another material into the fabric (such as cotton or synthetic) to create a more forgiving material to work with and enable faster production, resulting, for example, in half-linen fabric.

During weaving, problems arise that must be handled by our mechanics and machine operators. It could be a thread breaking in the warp, tangles with the weft yarn, or loops at the edges. When this happens, the fabric isn't approved as first-grade, and we can't use it for our products. However, since the material still retains its functionality, we sell it in our factory shop as second-grade so that customers can hem and use it themselves. Linen lacks elasticity, which means looms can't operate as quickly, and production must take its time. To improve the yarn's performance in the machines, a higher humidity level in the air is needed. By introducing steam into the ceiling, we achieve an air humidity of about 70%, preventing the material from becoming brittle during the weaving process.

Seams are the weakest link in the fabric, and there is the greatest risk of the material tearing there. Therefore, we weave our products in finished width, meaning if it's a towel that's 50 cm wide, we weave a fabric that's 50 cm wide, and thus we only need to hem two sides. In our weaving mill, there are 14 looms. In each warp, we can weave a certain number of products depending on the sleying. To create the right pattern for each product, we start from a "pattern template" and make pattern cards for the machine. Our oldest machines have wooden pattern cards, machines from the 1970s have plastic punch cards, and our newer machines from the 2000s are programmed using a computer.